BBRT

Black Body Radiation Textile, otherwise known as BBRT, is the principle behind the uniform utilized by special forces personnel in Sayaffallah as a way of providing covert access during nightfall exercises. This article will explain the principle behind black nbody radiation and more importantly how this important technology works so that troops of Sayaffallah can be kept safe even in the most dangerous of battlefield operations

Black body radiation theory

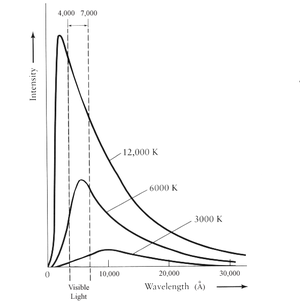

Matter is all around us in every object around us, and as energy flows through an object it affects the amount of light that can be seen in an object or coming from an object. Yet a black body refers to an opaque object that emits thermal radiation. A perfect black body is one that absorbs all incoming light and does not reflect any. The diagram to the right demonstrates that as energy or temperature increases the amount of light wavelengths changes. Yet there are two instances in which the light wavelength either is transformed completely opaque or does not reflect any light at all thus rendering the object either invisible or completely black.

When an object is receiving negative kelvins or producing a reaction aimed at reaching the point of absolute zero (−459.67°F/ −273.15°C) the opacity of an object is given the same effect as if it were at the highest point of energy reception yet it is unable to replicate the same effect as receiving a perfect black body reaction. The problem lies in the transference of extreme kelvins into a textile without triggering the combustion or melting point of a given textile in a uniform application. A uniform must be able to be heated to the point of achieving absolute black without injuring or harming the wearer while another uniform must be able to achieve absolute opacity without harming the user through the cooling of the fabric.

Planck's Law as shown above illustrates the principle that as energy increases the corresponding wave length also increases thus creating an effect of brighter light spectrum. As an object is heated it changes color until it eventually reaches total transparency typically around seven times its melting point. Because it requires hitting such a high level of proportionality constant between the minimal increment of energy, E, of a hypothetical electrically charged oscillator in a cavity that contained black body radiation, and the frequency, f, of its associated electromagnetic wave.

Textile production testing

Researchers found that as electromagnetic energy increased it was possible to replicate the same effect achieved through direct heating of a textile property thus creating the ability to reach total black state without the need for heating beyond the melting point. Electromagnetic energy was increased using particle replication technology in which particles on a purely subatomic level are accelerated in a fixed array towards a given object or in this case textile. As the energy is transferred into the textile it bounces off of the textile and grounds itself into the nearest transference point. The transference point must be resilient enough to withstand the concentrated energy of the electromagnetic exchange in order to serve its purpose as a neutral transference point.

Initial testing was conducted and found that none of the energy penetrated through the total layers of the textile fabric in the uniform and that the wearer was shielded from any energy residue from the transference because of the elasticity of the material employed. The material consists of black carbon powder similar to that type of powder used in dying tires into the black color typically seen. The black carbon powder creates a resin like coat on the outside of the material that enables the transference of energy to be sent into another object so that it does not remain on the textile and thus provide a hazard to the wearer. Tests found that the effect of reaching absolute black body radiation was sufficient as to turn the textile beyond the point of human seeing yet it relies upon no further transference of positive energy into the suit meaning that the textile would be rendered ineffective and useless in standard daylight in which the electromagnetic transference of natural sunlight into the suit would negate the overall intended effect.

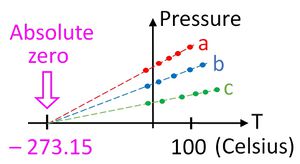

On the other side of the coin was the need and desire to attain maximum opacity of the wearers textile without subjecting the user to extreme cold temperatures necessary for achieving the absolute zero. The key to this was to reverse the absolute zero formula and to utilize it in conjunction with Lussac's law. Lussac's law states that as absolute zero is achieved pressure steadily increases and builds so in order to replicate the effects of absolute zero researchers found that storing the textile uniforms in a pressurized environment at cold temperatures they could replicate the effect of absolute zero and achieve the desired opacity of the textile. Researchers determined that by reversing the process and utilizing pressure first and introducing cold temperatures as a secondary feature they could achieve the same level of daylight opacity as they would have without it. The problem however came in regulating the continual cold needed for long hours of operation in order to maintain optimal opacity of the outfit. Researchers developed a self cooling outer layer utilizing Freon gas exchange to replicate cold while ensuring that the wearer remained insulated from the Freon for maximum benefit. The Freon gas exchange maintained the overall opacity for a significant duration time and ensured that the textile would remain effective for the duration of use as long as the Freon was replaced at established intervals.

Modern application

This technology is presently used by the Armed Forces of Sayaffallah particularly special forces divisions that need opacity in their uniforms to blend in with natural environments and black body suits to maintain optimal night time effectiveness. Due to the sensitive nature of this technology only the most basic of information has been shared with media, those with knowledge state that new advances are ongoing and the textile is under constant improvement.